9/18/2020

BY: ROGER TOMLINSON

In the ongoing pursuit of improving profitability, is it more important for a company to reduce costs or increase revenue?

In the ongoing pursuit of improving profitability, is it more important for a company to reduce costs or increase revenue?

The answer to this complex question likely depends on many factors, including the type of company in question, industry trends and market conditions. Each strategy has its own benefits and drawbacks – but which is best for your company?

INCREASING REVENUE TO RAISE PROFITS

If a company chooses to raise revenue, where is the best place to start? One common strategy for increasing revenue is to establish higher prices.

Customers typically do not choose something solely based on price, but instead quality. Most customers will pay more for a product or service that they think is made well or exceeds standards. The reason Rolex can price its watches higher than any other in the industry is because the company has established a long history of delivering superior products. Quality products help to maintain customer satisfaction and loyalty while reducing the risk and cost of replacing faulty goods.

To build a reputation for quality like this, companies can start by gaining accreditation with a recognized quality standard. In some instances, adherence to a recognized quality standard may be essential for dealing with certain customers or complying with a specification, policy, standard or law. Many companies insist that their suppliers achieve certification to quality standards. If the business sells products in regulated markets, such as healthcare, food or automotive goods, they must be able to comply with health and safety standards designed to protect consumers. Certified quality management systems play a crucial role in complying with those standards. Accreditation also can help to win new customers or enter new markets by giving prospects an independent confirmation of your company’s ability to supply quality products. In a similar way, if a business consistently delivers what it promises, customers are much more likely to spread the word. This helps drive brand awareness. With this improved reputation comes the ability to raise prices and revenue without losing customers.

REDUCING COSTS TO RAISE PROFITS

Reducing costs also can increase profitability, but only if sales prices remain constant. If cost reductions result in a lowering of the company’s quality, then the company may be forced to reduce prices to remain at the same level of sales. If a company can reduce costs by optimizing the supply chain, manufacturing operations, personnel and facilities without having an impact on quality, sales price or sales volume, that provides a path to higher profitability.

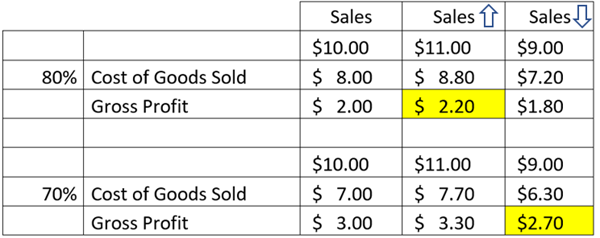

An evaluation of all Cost of Goods Sold (COGS) is necessary to determine where opportunities to reduce costs exist. COGS refers to the direct costs attributable to the production of the goods sold in a company. This amount includes direct materials, direct labor and manufacturing overhead costs.

A demonstration of this method of increasing profits can be seen in the calculations below.

When it comes to maximizing profits, both raising revenue and minimizing costs can help companies reach their profitability goals. It is up to the company to decide which strategy will work best for them and their unique challenges. To help manufacturers with these goals, The Center offers a variety of tools targeting quality, costs and efficiency. Learn more about our personalized consulting and training offerings here or contact inquiry@the-center.org to speak with our experts today.

MEET OUR EXPERT

Roger Tomlinson, Lean Program Manager

Roger Tomlinson, Lean Program Manager

Roger has been a Program Manager at The Center for 18 years. He has trained and mentored hundreds of Michigan manufacturers in the entire portfolio of Lean strategies and methods (e.g., Kaizen events, Standardized Work, 5S/Workplace Organization, Value Stream Mapping, Total Productive Maintenance, Culture Change, Team Building, Operations Management and Process Re-Engineering). In addition to his training and consulting work, Roger has more than 20 years of experience in manufacturing management.

Since 1991, the Michigan Manufacturing Technology Center has assisted Michigan’s small and medium-sized businesses to successfully compete and grow. Through personalized services designed to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.the-center.org.

Categories: Finance