10/12/2018

BY: CHUCK WERNER

In past posts, we’ve talked about the relevance and applications of implementing technology, highlighting the advantages that such innovations can bring to manufacturers of all sizes. But what does it actually look like when these technologies are leveraged to improve a business? For a more detailed picture, let’s take a quick walk through the stages of business maturity.

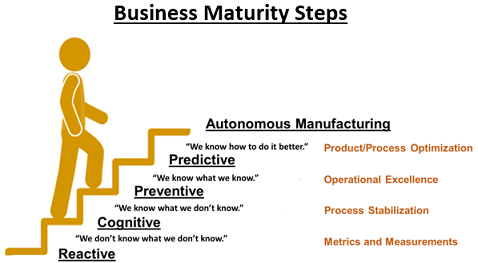

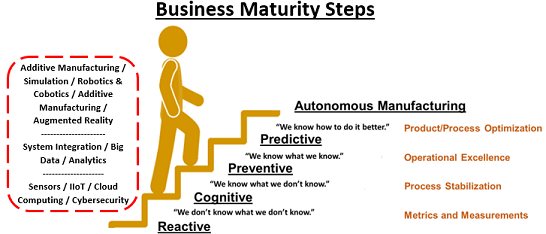

There are several different maturity models for business development, but the one we will use is outlined below:

Some say the journey is the most important part, but having a destination is the only way to know when you “get there.” For the purpose of this blog, let’s propose that the goal of an organization is to achieve autonomous manufacturing. This is an environment of flexibility within the business. While this flexibility can manifest itself in different ways, it can be fundamentally defined as the ability to have real-time identification and reaction to variation in a product, process or service. In an autonomous environment these deviations would be detected and responded to (correctly) by the appropriate (lowest possible) level of the organization.

How can an organization reach this level of flexibility and autonomy? As seen in the figure above, a business starts out as a reactive organization, where a centralized group of decision-makers attempt to resolve issues with little to no advanced warning in a ritual we affectionately call “firefighting.” To escape the constant chaos of their reactionary existence, the organization takes specific steps to improve their management to the cognitive level. The introduction of metrics and measurements provides the first clear glimpse of performance, allowing workers to locate sources of variation. Standard systems and procedures are then put in place and serve to stabilize the environment, as well as enable the business to operate in a preventive manner. Soon it becomes obvious which issues are resulting in poor performance. Reaction plans are implemented to ensure effective and timely responses to minimize the impact of variation. Additionally, focused projects are improved to empower the organization to predict situations that cause variation. Now a predictive organization, the business begins to foresee these situations and is able to identify and implement improvements in processes, products and services to eliminate occurrences of variation. Each step moves the process closer to the desired level of flexibility until the organization performs more like an organism, with each part reacting autonomously to support the well-being of the whole.

Technology Can Help You “Get There”

Taking a business from its original form and guiding it to become a learning organization is a challenge. A lot of heavy lifting can be involved and, quite frankly, many people are so tied up in day-to-day operations that trying to find the time and information to work on the business can be difficult. Unless a company is blessed with a “people closet” to supply additional support, the efforts may fall short in either resource or priority, causing the improvement initiatives to fail. To combat this challenge, leveraging technology can reduce the resource drain on the leadership team and result in improvements that are not only realized faster, but are easier to sustain and build on in the future. Let’s consider the benefits of using technology to assist in each level of business maturation:

Beginning in the reactive phase, an organization “does not know what they do not know,” meaning they are unaware of how their business is really performing. In order to progress and improve their operations, they must begin gathering data to gain more insight into the strengths and weaknesses of their current practices. However, asking people who are already task-saturated to fill out additional paperwork is never a popular move – and it doesn’t stop there. That paperwork also must be collected, tracked, compiled, reported and shared before it can even be considered. This additional demand on resources can result in failures to collect data as well as delays in receiving it. Using sensors and the Industrial Internet of Things (IIOT), the data collection process can be automated so that additional burden is not placed on team members. And, rather than keeping file cabinet after file cabinet of stored sheets, the data can be saved electronically on-site or in the cloud in a secure manner.

But, as has been noted many times by many people, data is just data until it is actually analyzed and turned into information. It is only then that the organization “knows what they don’t know,” growing in maturity in the process. They also learn that there are pockets of information existing which should be available to a larger number of team members. Using dashboards to provide real-time information and system integration, a greater number of resources can be used to understand the information and identify ways to prevent, and eventually predict, when a negative or unusual outcome is about to occur. Since the Big Data generates itself, the body of information available will be much larger and more accurate than previously. As the team begins to identify Key Input Variables (also known as leading indicators), they can use the integrated systems and dashboards to communicate the likelihood of issues before they occur, effectively operating as a predictive organization, allowing the team enough time to take appropriate actions. Again, technology enables the team to achieve more with the resources they have, rather than asking more of already-taxed resources.

Once the organization has reached the point of trying to optimize business practices and begins looking at ways to design all variation and waste out of their products, processes and services, technology should again be considered. Ask yourself, for example, if inspection failures are an issue, can the process be automated through cobotics/robotics to ensure 100% performance of the task or to reduce measurement inaccuracies? Can augmented reality be used to provide relevant data in real time or to assist team members in achieving a higher level of training? Through simulation and virtualization, can failure modes be better predicted and then eliminated? And finally, could your product be better made using additive technologies rather than subtractive? Leveraging technology at this level to support product, workforce and process improvements can ultimately help a company achieve and maintain autonomous manufacturing.

Manufacturers often are intimidated by technological implementations due to the high costs, time and labor they assume they will have to invest. But, if effectively applied, technology can help team members achieve a new level of efficiency through the delivery of real-time information. This allows them not only the flexibility to respond to (and capitalize on) situations, but also provides them with time to focus on ways to improve practices and work autonomously.

The Center is here to guide manufacturers through their technological implementations in a way that makes sense for their businesses. From an initial assessment to identifying and applying relevant technologies, we can assist. To learn more about how we can support your company’s Industry 4.0 journey, contact us at

inquiry@the-center.org or call 888.414.6682.

MEET OUR EXPERT

Chuck Werner, Lean Program Manager

Chuck has been a Lean Program Manager at The Center since 2016. His areas of expertise are in Lean, Six Sigma and Quality. Chuck has devoted many years to practicing Six Sigma methods, ultimately earning a Six Sigma Master Black Belt in 2011. He is passionate about helping small and medium-sized manufacturers become more prosperous using a variety of tools and methods gathered from over 27 years of experience. Additionally, Chuck is a certified ISO/QS9000 Lead Assessor, Training Within Industry (TWI) Master Trainer and is certified in OSHA Compliance and Accident Reduction.

Since 1991, the Michigan Manufacturing Technology Center has assisted Michigan’s small and medium-sized businesses to successfully compete and grow. Through personalized services designed to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.the-center.org.

Categories: Advanced Manufacturing,

Industry 4.0,

Innovation,

Technology