10/14/2016

We all agree on the benefits of embracing a Six Sigma  Culture. It is after all a management methodology which allows companies to use data to eliminate defects and reduce variability in any process, manufacturing and business alike.

Culture. It is after all a management methodology which allows companies to use data to eliminate defects and reduce variability in any process, manufacturing and business alike.

Yet, it is also important to know that in Six Sigma there are two main methodologies both inspired by Deming’s Plan-Do-Check-Act Cycles, and each is composed of five phases:

- DMAIC (Define, Measure, Analyze, Improve, Control) brings improvement to existing processes, services, and systems, and it is more universally used and accepted, whereas

- DMADV (Define, Measure, Analyze, Design, Verify) is used by organizations that are involved in continuous development, mostly done from scratch, and design/re-design as well as innovate new products and services

Basically, the Design phase is the only difference between DMAIC and DMADV.

Design for Six Sigma

We also hear a lot about the DFSS (Design for Six Sigma) methodology that some companies embrace. So you may ask, what is the difference between DMAIC and DFSS?

DFSS aims at designing new defect-free products or services to meet CTQ (Critical to Quality) factors that will lead to customer satisfaction; this approach is all about preventing problems. DMAIC, on the other hand, focuses on detecting and solving problems with existing products and services. Furthermore, DMADV and DFFSS are so similar, that we can view DMADV as the vehicle to implement DFSS.

After all, it was Motorola that started it all in 1986! But it was Jack Welch at GE who in 1995 glamorized Six Sigma and advanced it to a household name status by making it central to the company’s business strategy. Honeywell and Ford soon followed. By the late 1990s, almost two-thirds of Fortune 500 companies had begun Six Sigma initiatives in their efforts to reduce costs and improve quality. Companies attributed billions of dollars in savings and process improvements to their Six Sigma Initiatives. It seemed that Greatness was achieved!

But… Wait! Where Does Lean fit In?

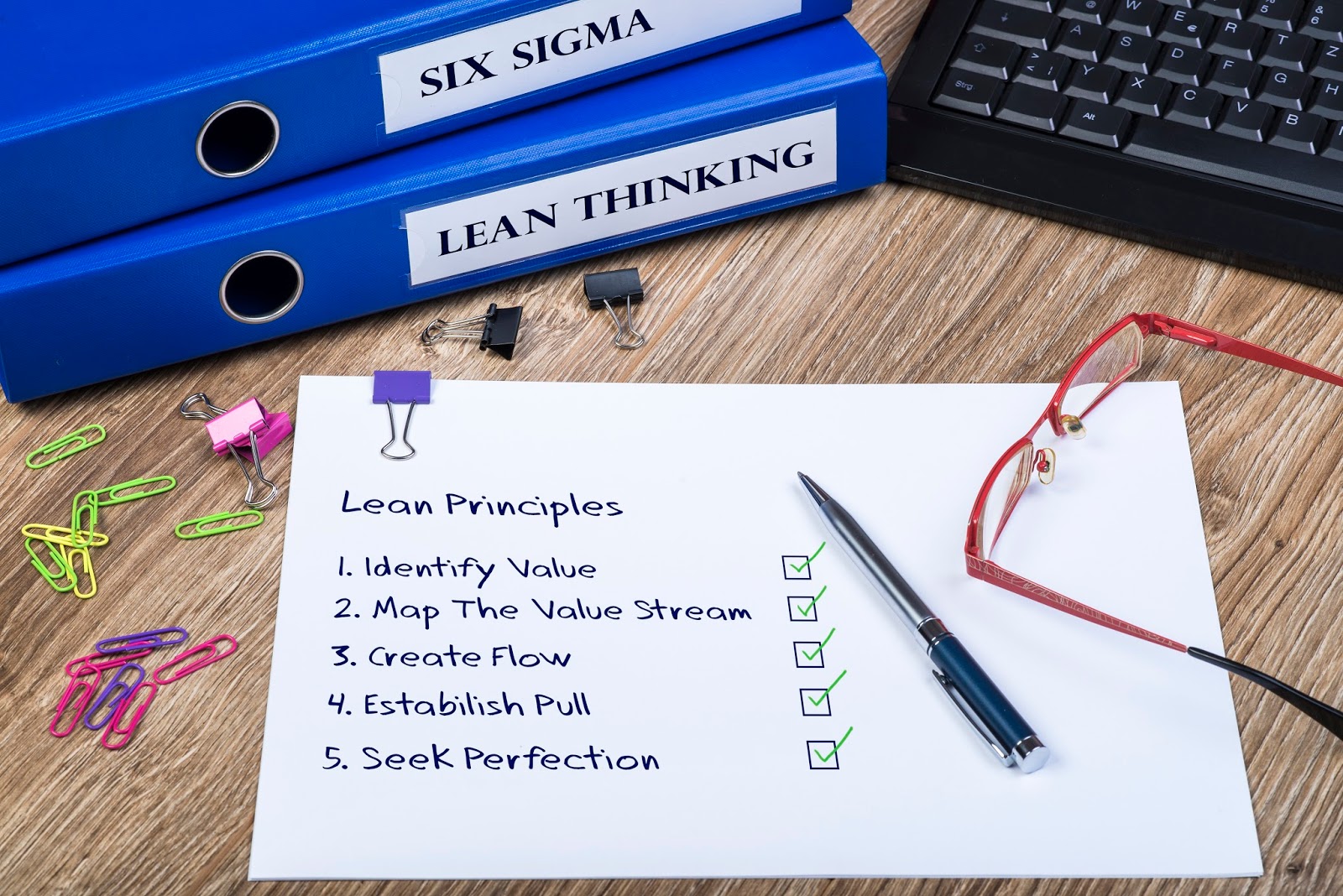

Practicing Lean adds value to an organization, process, or system by reducing non-value added activities and standardizing work. Lean implementation focuses on getting the right things to the right place at the right time in the right quantity to achieve perfect work flow, while minimizing waste and being flexible and able to change. It makes work simple to understand, easy and manageable.

Today, Lean management has permeated any and all areas of an organization. It has gone beyond just manufacturing and is viewed as an approach of running an organization that supports the concept of continuous improvement as a long-term approach to systematically achieve small, incremental changes in processes for improving efficiency and quality.

Integrating and Implementing Lean and Six Sigma

Although Lean and Six Sigma are two different paradigms, they share similar methodologies and tools. Six Sigma, for one, reduces process variation and eliminates defects by using statistical data analysis, hypothesis testing, and in some cases - when appropriate DOEs (Design of Experiment). Lean, on the other hand, drives out waste and promotes work standardization, but utilizes less technical tools such as Kaizen, workplace organization, and visual controls.

The most successful implementations starts with the Lean approach of making the workplace as efficient and effective as possible. Once Lean implementation has been completed and process problems still remain, the more technical Six Sigma statistical tools may be applied. It makes perfect sense to do that because one thing they both have in common is that strong support from leadership is required in order to make them the standard way of doing business. You can’t have one without the other!

Eventually, when Six Sigma methodology married the Lean philosophy, their offspring was Operational Excellence! GE, Verizon, IBM, just to name a few, have successfully and profitably used Lean Six Sigma to transform their enterprises, promote innovation throughout their organizations, and achieve lucrative growth.

But what about me? I am a small or at best a medium sized company! What can it do for me?

Although the approach of implementation may be slightly different given the size of a company, the needs and drivers that make organizations want to adapt the Lean Six Sigma dogma are the same regardless of size.

Let’s analyze some of the most common reasons organizations give for not adopting Lean Six Sigma into organization:

- We can’t afford the cost. Lean Six Sigma is indeed an investment. If the methodology is followed as it’s designed, the return of the investment of training even a couple of people in the organization will more than pay for itself right away. Start small, and build as needed. With the right projects, a couple of green belts should yield savings that by far exceed the cost of training them!

- We don’t have the time and are too busy putting out fires. It is a fact that time is any organization's most valuable commodity. When you waste it you are throwing away an irreplaceable resource. Putting out fires is an on-going vicious circle of being perpetually reactive to perennial problems instead of being reactive and fixing them once and for all. You owe it to yourself and your business to invest some time in understanding how Lean Six Sigma can help you.

- We are too small. Lean Six Sigma is for large companies. This is one of the most common reasons small and medium-sized companies provide for not implementing it in their organizations. Just think that there have been two person start-ups using it with excellent results. Did they do a full Lean Six Sigma transformational deployment? Of course not! But, by consistently using key principles such as the Voice-of-the-Customer, they were able to help translate customer needs into their specific service offerings.

- We are not a manufacturer. Well, neither is Coca-Cola Company, Bank of America, Starbucks, and Wal-Mart just to name a few. Although Lean Six Sigma originated in manufacturing, the principles apply equally to transactional and service environments. In fact, the service industry actually has more waste than manufacturing does because so much of the work and deliverables are "invisible" and not in the form of tangible widgets as in manufacturing.

- Lean Six Sigma involves a lot of statistics and advanced mathematics. Most of our employees are front-line operators and not engineers The great majority of small and medium organizations do not require statistics and advanced mathematics to enjoy the benefits of Lean Six Sigma. Most of the principles and tools can be quickly and easily used by anyone if the training is done properly.

- Lean is a better fit for our business. We're going to start with Lean and then move into Six Sigma. Believing this cheats your customers, your employees, your business and yourself. Lean and Six Sigma are not mutually exclusive nor do they have to be applied in a linear fashion. They complement each other. By combining efficiency and effectiveness you get dramatic results. By only doing Lean you sacrifice the benefits of quality. Likewise, when you only implement Six Sigma you miss out on driving efficiencies.

- We tried Lean Six Sigma years ago and did not achieve good results. The first thing to ask yourself is ‘Why didn’t you achieve good results’. How was "success" defined? Was the result of lackluster outcome related to people, processes, or technology?

Regardless of the reasons, you owe it to your customers, your employees, your business, and yourself to try again. Maybe this time you need to take more time on the front end to clearly articulate the vision of your organization moving forward. Define the problems you are trying to solve with a program like Lean Six Sigma. Engage the front line and your customers to be part of the process. Remember, a methodology like Lean Six Sigma is only as good as the people managing it and the processes they use to manage it.

If you’re a manufacturer who is looking to become more efficient, productive and globally competitive, the Michigan Manufacturing Technology Center can assist you. Click here for a list of our services or contact us at 888.414.6682 or via email at inquiry@mmtc.org.

About Us: Since 1991, the Michigan Manufacturing Technology Center has assisted Michigan’s small and medium-sized businesses successfully compete and grow. Through personalized services fitted to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at on the web at The-Center.org.

Categories: Lean Principles,

Six Sigma