10/31/2014

Over the last few weeks, we’ve talked about Managing or Mitigating Risk, The Value of Positive PR, and Competition, namely Supply Chain vs. Supply Chain and the importance of minimizing disruptions. As technology and other advances make the world seem smaller and smaller, it’s more important than ever to prepare in advance for potential service disruptions. As stated last week, we want to ‘remove the blindfold’ before entering the obstacle course.

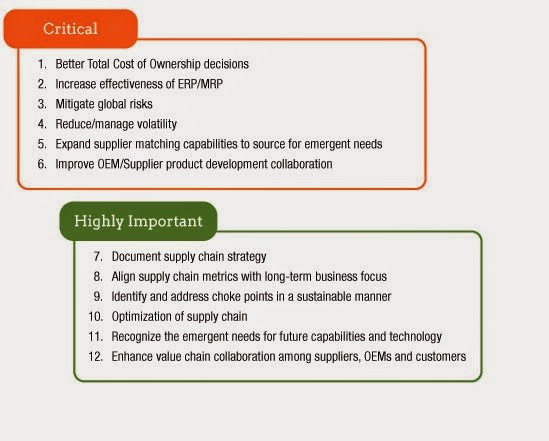

The National Institute of Standards and Technology’s Manufacturing Extension Partnership (NIST-MEP), our federal sponsor, conducted research to identify the critical needs of supply chains. Through a two-phase survey process, 12 competitiveness drivers were discovered and the six most critical highlighted.

The National Institute of Standards and Technology’s Manufacturing Extension Partnership (NIST-MEP), our federal sponsor, conducted research to identify the critical needs of supply chains. Through a two-phase survey process, 12 competitiveness drivers were discovered and the six most critical highlighted.

In response, MEP experts, including MMTC's own Roger Tomlinson, are working hard to roll out a program to address these issues. MMTC has long assisted parent companies with integrated solutions for their locations. We see this as a further step, one that connects individual company improvements to supply chain benefits. Key supply chain benefits include:

Alignment Visibility Collaboration Optimization

Fundamentally, Supply Chain Management (SCM) is about reducing risk, not just to manufacturing but across the entire quote-to-cash cycle.

Risk Management

A healthy supply chain is the foundation of any successful organization. Rapid and dynamic changes occur daily both inside and outside every organization. That is why it is important to plan for and have low-cost tools in place for dealing with potential disruption.

Supply chain decision-makers, along with senior management, must understand and utilize risk management practices to manage and control all critical points along its network. A good understanding of risk management techniques becomes the foundation that allows managers to make more informed distinctions among the competing priorities of process cost-effectiveness and risk exposure. A sufficiently robust supply chain will be able to model a good number of alternatives, to know what is feasible and what is not feasible, and to be able to present metrics on the cost to reduce the risk of possible disruptions.

Not Just Risk in Manufacturing

‘Total Cost of Ownership’ is what SCM means when it addresses risk, not just to on-time production, but to the entire cycle from purchasing to delivery. Total cost of ownership captures all pre-transaction, transaction, and post-transaction costs and also includes the total landed cost element if some or all of the materials are imported from another country.

The consequences of getting this wrong are very high. If a company does not identify all of the cost factors, it may under-quote the price to the customer. This could result in selling products below cost. Understanding the total cost of ownership also improves the company’s chance of meeting all licensing, regulatory, and logistics requirements. Non-compliance can cost an organization additional penalties and delays.

The international transportation of goods falls under the International Commercial Terms, also known as Incoterms, of which there are 11:

- Pickup at supplier

- Inland transportation to a port or airport

- Origin terminal and port fees

- Export licensing, documentation, and duties

- Ocean or air carriage

- Import documentation and duties

- Terminal and port fees at destination

- Customs review

- Harbor maintenance fees

- Maritime insurance

- Inland transportation to importer’s location.

The Incoterm agreed on between the importer and the supplier determines the responsibilities of each party and, therefore, the division of costs. Before a buying organization can begin to calculate the total cost of ownership, it must identify the Incoterm that will be used in the transaction. That selected term will clearly define who does what and which factors should be included in the buying organization’s calculated total cost of ownership.

For a complete overview of MMTC’s Optimization program, join us on Nov 5th at 8:00 am and discuss benefits to you and your community of partners. Find out how to create a stronger base for your manufacturing processes through this half-day. An in-depth look at the Roadmap to achieving the four key benefits and the accompanying tools will help you decide whether Supply Chain Optimization is right for you..

Since 1991, MMTC has assisted Michigan’s small and medium-sized businesses compete and grow. Through personalized services fitted to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.mmtc.org.

Categories: Supply Chain