10/24/2014

According to Miriam Webster, competition is “the act or process of trying to get or win something (such as a prize or a higher level of success) that someone else is also trying to get or win: the act or process of competing.”

This is something we’re all familiar with, and at the top of our minds as one of Michigan’s biggest sports rivalries of all time, the competition for the Paul Bunyan Trophy, takes place this weekend. The University of Michigan Wolverines and the Michigan State Spartans will take the field at Spartan Stadium in East Lansing this Saturday at 3:30 for their 107th meeting. The Wolverines currently lead the series, 68-33-5.

While the outcome is of interest to hundreds of thousands of fans and the winner will receive bragging rights for the next year, at the end of the day not much will change. [No offense intended to football fans everywhere. Indeed, this author is a huge fan of the game, but football rivalries pale in comparison to weightier issues.]

In business, competition is a little more serious, and the fallout from failures is more far-reaching. Particularly in manufacturing, competition is no longer limited to the U.S. vs. Low Wage Nations, Nation vs. Nation, Industry vs. Industry, or even Company A vs. Company B. More and more, it’s becoming Supply Chain vs. Supply Chain. How strong you are is dependent upon the weakest link in the network of companies that support your ability to purchase raw materials, process your parts, and move them along to your end user.

As part of the National Institute for Standards and Technology’s (NIST) Manufacturing Extension Partnership (MEP), MMTC is excited about a robust new program for Supply Chain Optimization that is being developed. We’ll provide more on the program next week. For now, one of the most important questions you can ask is, what do you do with a broken supply chain? Thankfully, Anthony Cerilli, Engagement Manager at our sister center, Genedge Alliance in Virginia has an excellent response. We include it below, in its entirety:

Fix it, of course. Though that’s never as easy as it sounds.

Supply chain disruptions are not a matter of if, but when. High-impact events that were once considered very low probability — “black swan” events — sometimes seem to be almost regular occurrences. While not all such events reach the magnitude of the 2011 Tōhoku earthquake and tsunami, over 200 natural disasters occur annually across our globe. With our globally interconnected business environment, problems that used to remain isolated now have far-reaching impacts.

If we accept that disruptions will happen, the question then becomes, how disruptive must they be? Organizations can mitigate the effects of supply chain disruptions by applying the principles of supply chain Risk Management and Visibility.

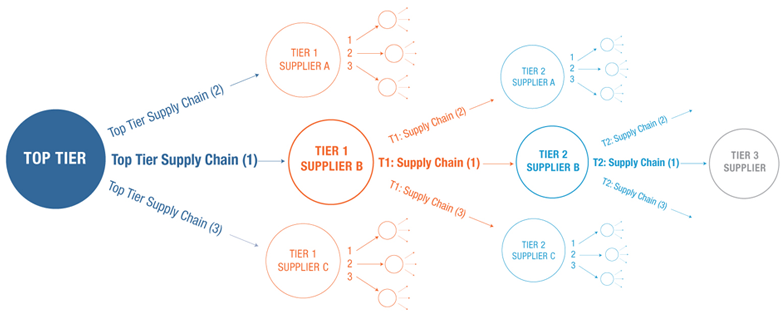

Is it any wonder why, in the same survey, nearly 20 percent of organizations said it takes 3 weeks or longer to assess the impact of unplanned disruptions?Global Manufacturing Outlook, 75% of respondents experienced at least one incident that caused significant disruption, with 42% of disruptions originating below the Tier 1 supplier. Unfortunately, however, over 50% of organizations have no visibility beyond Tier 1 (according to the 2013 KPMG study, Supply Chain Resilience 2013 survey by the Business Continuity Institute). A supply chain without visibility into all of the supplier relationships and processes is like trying to navigate an obstacle course blindfolded. You might make it through, but not quickly, and probably not without injury. The lack of visibility actually increases the risk that you will get injured, and a lack of visibility into a supply chain increases the risk that snags will become snarls and disruptions will become disasters. To effectively deal with supply chain risks in our global environment, an organization must look deep into the supply chain and work as hard as possible to predict potential problems and then, in true risk management style, develop ways to prevent the problems — if possible — or if they can’t be prevented develop plans to deal with them before they happen. An effective Risk Management program will anticipate and react to triggers as deep in the supply chain as possible.

The world is not going to get any less chaotic in the near future. Are you prepared for the disruptions that are almost sure to come your way?

Check out the MEP Network’s Supply Chain Management program website to find a Supply Chain Management Overview session near you, or complete the initial Supply Chain Vitality Quiz and get connected to your MEP Center. MMTC is hosting just such an event on Wednesday Nov. 5th, at our Plymouth office, from 8:00 am to noon. We’d love to see you there.

Since 1991, MMTC has assisted Michigan’s small and medium-sized businesses compete and grow. Through personalized services fitted to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.mmtc.org.

Categories: Supply Chain