11/10/2017

BY: ROGER TOMLINSON

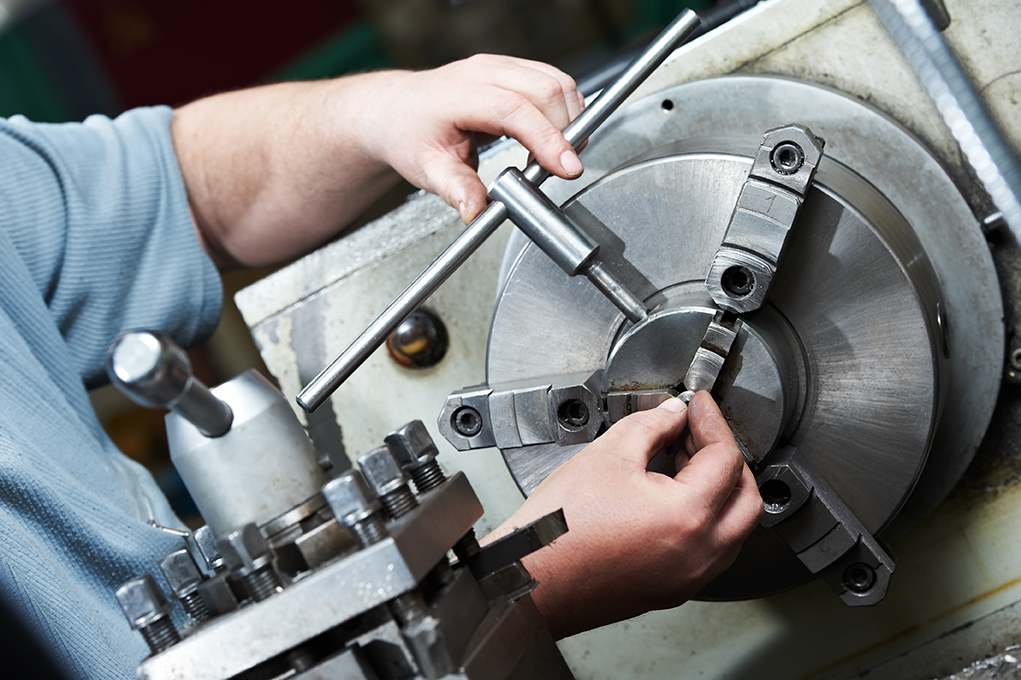

Manufacturers couldn’t exist without machinery, and keeping that machinery functioning and up-to-date is essential to productivity and success. While that sounds simple in theory, buying new machinery can be extremely pricey in reality. Fortunately, there is an alternative option that some manufacturers opt for: buying used machinery. Much like buying anything that is used, used machinery is often written off as being too big of a risk. However, used products have proven themselves in the past to be just as good as new products, if you don’t mind the presence of a few dings and scratches. That being said, there is a way to go about purchasing used machinery that minimizes the risk of unintentionally acquiring a faulty machine.

Manufacturers couldn’t exist without machinery, and keeping that machinery functioning and up-to-date is essential to productivity and success. While that sounds simple in theory, buying new machinery can be extremely pricey in reality. Fortunately, there is an alternative option that some manufacturers opt for: buying used machinery. Much like buying anything that is used, used machinery is often written off as being too big of a risk. However, used products have proven themselves in the past to be just as good as new products, if you don’t mind the presence of a few dings and scratches. That being said, there is a way to go about purchasing used machinery that minimizes the risk of unintentionally acquiring a faulty machine.

It is important to note that there is no correct way to buy used machinery, whether it be through online or in-person auctions, online retail sites, or in-person sales or trades. This process should be handled with care and smart decision-making to avoid spending more money on a used product than you would have on a new product.

4 USEFUL TIPS FOR BUYING USED MACHINERY

Do Your Research

After deciding which piece of machinery your facility needs, take the time to find a few different options of models and sellers from which to buy. Note the prices of the machinery, both new and used, to ensure that the price difference is worth buying used. Furthermore, keep in mind that the price of used machinery will vary depending on its condition. If something seems too good to be true, it probably is. You’re looking to save money, but purchasing the cheapest option may lead to endless bills in the future put toward fixing a faulty used machine. Always remember to investigate the individual or place that is selling the machinery as well. It’s best to inspect the machinery in person first if possible (especially when buying from an individual), but if you’re purchasing online, be sure to buy from a reputable seller.

Ask the Right Questions

It does not matter if you are buying from a used machinery company, individual seller, or broker – it is essential that you do your research. Ask your contact directly about the history of the equipment. If they are reluctant to answer, this may be a warning sign. Remember to also request references if you are buying from a used equipment company or broker to ensure credibility.

Unfortunately, purchasing products online has made it more common for customers to be easily deceived. Pictures can prove to be misleading or even fake. This can result in the customer being left with a product that is in much worse condition than they were promised, or even an entirely different product than expected. Avoid these disasters by creating a list of questions to ask the seller that will reveal details about the machinery you are considering, such as:

- How many previous owners did the equipment have?

- Why is the current owner looking to sell it?

- Can they offer their personal knowledge of the machinery’s specific working capabilities?

- Can they provide a preventative and breakdown maintenance log for the machine?

- How long has the machinery been stored at its current location, and is it stored in a warehouse?

- What is the age of the machinery, and has it been reconditioned? If yes, when?

- Will mechanics and electricians test-run the machinery before shipment? Will they provide any guarantee that the machine is in good working order before it is shipped?

- How has the company dealt with problems in machines they have sold in the past?

- What is their return policy?

- Will you receive timely assistance if a machine should have mechanical or electrical issues once in production?

Try Before You Buy

Review the machinery under power before purchasing it. This is a foolproof way to discover if the machinery is in good shape. Although this may not always be possible depending on the situation, be sure to take advantage of an opportunity like this if it arises!

Negotiate

After understanding the condition of the machinery, it is fair of you, as the buyer, to suggest a price that you think is reasonable. If you feel that the price of the used machinery is too high, don’t be discouraged to suggest a lower price – the worst that can happen is the seller says “No”! The whole point of buying used machinery is to save money, so it is worth trying to negotiate the price down.

Although purchasing used machinery may seem to be a daunting task, it can save a considerable amount of money. As long as buyers take their time when considering which used products to pursue, and precautions are taken every step of the way, there should be minimal issues throughout the process. Look for deals and reputable sellers so you can supply your facility with great machinery while saving a big chunk of change!

MEET OUR EXPERT

Roger Tomlinson, Lean Program Manager

Roger Tomlinson has been a Program Manager in The Center’s Lean Business Solutions program for 18 years. He has trained and mentored hundreds of Michigan manufacturers in the entire portfolio of Lean strategies and methods (e.g., Kaizen events, Standardized Work, 5S/Workplace Organization, Value Stream Mapping, Total Productive Maintenance, Culture Change, Team Building, operations management and process re-engineering). He is also involved in Transactional Lean Office, which identifies and eliminates waste in the office areas in a company.

Since 1991, the Michigan Manufacturing Technology Center has assisted Michigan’s small and medium-sized businesses to successfully compete and grow. Through personalized services designed to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.the-center.org.

Roger Tomlinson, Lean Program Manager

Roger Tomlinson has been a Program Manager in The Center’s Lean Business Solutions program for 18 years. He has trained and mentored hundreds of Michigan manufacturers in the entire portfolio of Lean strategies and methods (e.g., Kaizen events, Standardized Work, 5S/Workplace Organization, Value Stream Mapping, Total Productive Maintenance, Culture Change, Team Building, operations management and process re-engineering). He is also involved in Transactional Lean Office, which identifies and eliminates waste in the office areas in a company.

Since 1991, the Michigan Manufacturing Technology Center has assisted Michigan’s small and medium-sized businesses to successfully compete and grow. Through personalized services designed to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.the-center.org.

Categories: Lean Principles