1/31/2020

BY: JOHN SPILLSON

Anyone with experience in the food processing industry would agree that a lot can go wrong when manufacturing food products. For example, many food processors experience issues with:

Anyone with experience in the food processing industry would agree that a lot can go wrong when manufacturing food products. For example, many food processors experience issues with:

- Improperly cooked products

- Creating inconsistent products from shift to shift

- Inadequate packaging

- Using too much or too little seasoning

- Packaging material

- Poor or inefficient handoffs between process steps

While most food manufacturers turn to food safety plans to address common food safety hazards, these plans fail to identify and prevent all other types of failures in processes. None of the examples listed above would fall under the category of “food safety hazard,” yet they can still lead to immense losses in productivity, profitability and customer satisfaction.

To ensure these food failures are identified and prevented ahead of time, Failure Mode Effects Analysis (FMEA) can help. FMEAs are a systematic approach to defining, managing and reducing risks in a given process or design. While typically applied in the automotive, defense and medical industries, this assessment tool can provide invaluable benefits to food manufacturers looking to improve processes and reduce costs by targeting food failures.

COOKIE CASE STUDY: WHAT COULD GO WRONG?

To better understand how FMEAs can assist food processors, let’s take a detailed look at the procedure for baking cookies, along with all potential failures.

Baking a batch of cookies successfully depends on a number of factors, including: time, cooking temperature, temperature of the product prior to baking, surface preparation of the baking tray and type of pans or oven used. Variability in any of these ‘inputs’ could lead to variability in the finished product, or ‘output.’ A deviation may not result in a food safety issue, but could lead to a failure that creates wasted resources, extra costs or lost customer trust in your ability and your brand.

After outlining these inputs, we must identify potential food failures within each:

- Cooking time

- Is this the same for every type of cookie baked?

- Does the operator know the proper amount of time needed to bake each batch?

- Is the timer reliable and accurate?

- Cooking temperature

- Is this the same for every type of cookie baked?

- Has the ideal temperature been determined?

- Is the thermometer reliable and accurate?

- Does the operator know the correct temperature for each cookie?

- Is the oven properly pre-heated?

- Cookie temperature at time of baking

- Is the product frozen, thawed or room temperature when baked?

- Surface preparation of the baking tray

- Is parchment paper required?

- Is pan release spray required?

- Type of baking tray

- Is the correct size being used?

- Is the correct type being used?

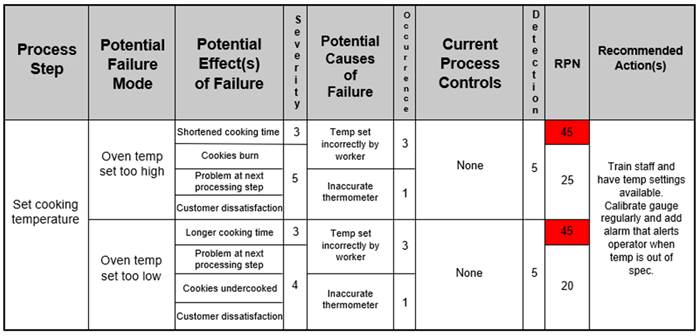

Once this has been identified, the FMEA tool can be applied to each factor to determine the severity of potential failures, the likelihood of one occurring and the method for detecting all failures. A ranking from one to five is then chosen for each of these three components – Severity, Occurrence and Detection – and multiplied together to establish a Risk Priority Number (RPN) for all potential failures. The lower the number, the less critical the failure is to address.

An example of this is shown below, where an FMEA is completed for one process step: setting the temperature of the oven.

As seen above, two RPNs are significantly higher than the rest (highlighted red). These should be addressed first, as they would yield the greatest positive impact. Training the staff and making the proper cooking temperatures available at the source would reduce the rate of occurrence significantly. Additionally, as there currently is no process in place to detect when the temperature of the oven is incorrect, adding some kind of system to alert the operator would help error-proof the baking process.

Going forward, this same detailed FMEA is conducted for each process step to identify potential failures, root causes and corrective actions.

A TRUSTED TOOL THAT PRODUCES REAL RESULTS

Most food processors only consider food safety in production, but neglect to consider food failures. But with so many associated costs, from productivity to customer satisfaction, failures are too serious to ignore. By using FMEAs to identify and prevent potential failures before they become a problem, improvements can be made at every level of production.

To help food processors manage risk with FMEAs, The Center offers a 1.5 day course geared specifically toward the common risks and challenges of food processors. To learn more about this course, click here.

MEET OUR EXPERT

John Spillson, Food Business Development Manager & Lean Business Advisor

John Spillson, Food Business Development Manager & Lean Business Advisor

John joined The Center in 2014 to develop and expand the food program. His experience in operating his own business has given him knowledge in production, sales, food safety, marketing, warehousing and logistics. John works to help companies understand that food processing is manufacturing, enabling them to embrace the same strategies that have aided traditional manufacturers for decades. As a Lean Business Advisor, John uses Lean tools such as Value Stream Mapping, 5S, Kaizen events, Standard Work and Problem Solving to help manufacturers of all types effectively reduce waste, improve efficiency, manage risk and improve corporate culture.

Since 1991, the Michigan Manufacturing Technology Center has assisted Michigan’s small and medium-sized businesses to successfully compete and grow. Through personalized services designed to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.the-center.org.

Categories: Food Processing,

Quality Management