1/29/2016

As governmental and consumer demand for decreased emissions, higher sustainability, lower carbon footprint and greater fuel economy increases, the growing trend for original equipment manufacturers (OEM) to adopt new materials is impacting manufacturing at all tier levels. As OEM’s change materials, small and medium-sized manufacturers will face a timely shifts toward aluminum, advanced high strength steel, composites, bio-polymers and bio-materials.

New and lightweight materials being specified by OEM’s in all industries pose a substantial risk to Michigan manufacturers. Changing materials mean developing new processes, modifying supply chains, investing in new equipment, learning new materials, and adapting manufacturing practices to new requirements.

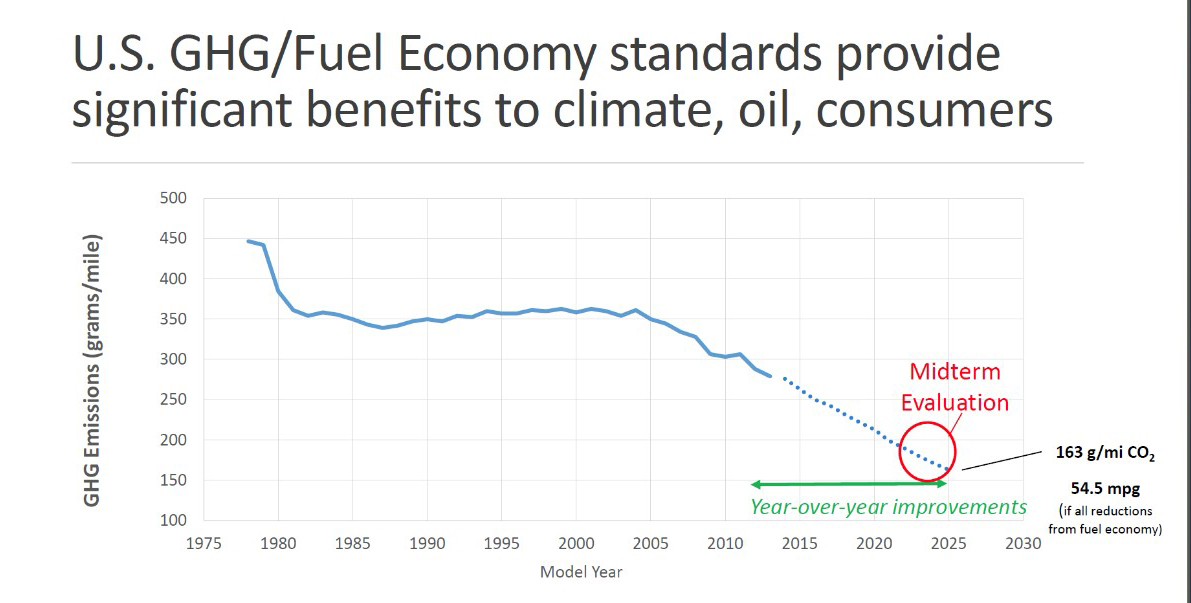

The fervor to reduce greenhouse gas emissions and increase fuel economy is stronger than ever at the EPA. Consumers and automotive companies are on board for continued improvements to meet the 2025 standard of 163 g/ml CO2 (54.5 mpg) average for all cars sold in the United States. European standards are even tougher, and China and other Asian countries are moving in the same direction. With the emphasis on global vehicle manufacturers, all from Detroit to Yokohama and Wolfsburg, are taking the fuel economy challenge very seriously. A midterm evaluation period is scheduled for June 2016, but it seems unlikely that the conclusions will be anything but to stay to course and push for 54.5 mpg average in 2025. See the following chart from the EPA.

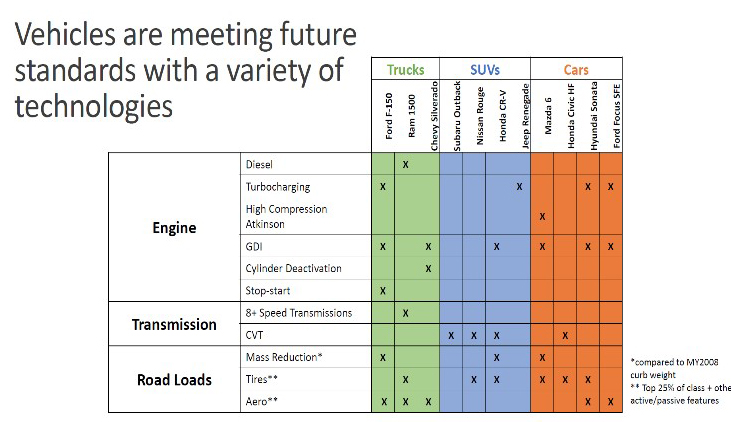

With average fuel economy still in the 25 – 30 mpg range today, how will the car companies reach the end goal? In his presentation to the Center for Automotive Research last August, Chris Grundler, Director of the EPA in Ann Arbor, presented the following charts showing that a number of vehicles are well on their way to achieving the vehicle class goals. The pathway to higher mileage includes improvements in engine technology, transmissions, and road loads. Reduction of mass is also playing a role with many of these models. This evidence points out that there is not one solution out there, but a combination of many that will get the car companies where they need to be.

Automotive companies are eager to reduce weight to offset weight increases created by safety features being added to vehicles. They are but they are not eager to increase cost.

MMTC Can Help You Meet Growing Demand for Lightweight Components

Altering existing materials means developing new processes, modifying supply chains, investing in new equipment, learning new materials, and adapting manufacturing practices to new requirements within your organization. MMTC’s Materials, Process and Product Consulting program will assist clients in better understanding the risks, upgrading processes, equipment and systems, and provide in depth technical know-how to assess clients capabilities and establish programs to significantly improve manufacturing efficiency and quality while preparing for new materials and products.

MMTC’s Areas of Technical Expertise

- Forming & Fabrication of Advanced High Strength Steel & Aluminum

- Welding, Joining and Heat Treating

- Casting – Aluminum, Iron & Magnesium

- Powder Metal Molding

- Metallurgy of Traditional & New Materials

Services Offered

New and lightweight materials being specified by OEM’s in all industries pose a substantial risk to Michigan manufacturers. MMTC’s Materials, Process and Product Consulting services can benefit your operations with:

- New Material & Job Quote advising

- Recognizing Changes in Scrap Handling & Recycling

- Preparing for the Future With Assessments, Waste Walks & Program Preparation

- Process Training & Development

- Design of Experiments

- Troubleshooting (8D Problem Solving)

- Program or Project Management

Contact MMTC

Do you have a materials or process-related question? For more information, call the MMTC Materials Tech Team today at 888.414.6682.

Since 1991, MMTC has assisted Michigan’s small and medium-sized businesses compete and grow. Through personalized services fitted to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.mmtc.org.

Categories: Advanced Manufacturing,

Data & Trends,

Technology