12/11/2020

BY: JOHN SPILLSON

When building anything of quality or value, you must first start with a solid base. You can’t build a house without a foundation, you can’t assemble a car without a frame, and you certainly cannot develop and maintain a robust food safety system without the foundation of solid Current Good Manufacturing Practices (cGMPs).

When building anything of quality or value, you must first start with a solid base. You can’t build a house without a foundation, you can’t assemble a car without a frame, and you certainly cannot develop and maintain a robust food safety system without the foundation of solid Current Good Manufacturing Practices (cGMPs).

cGMPs are covered in the Code of Federal Regulations (CFR) Title 21, which includes rules of the Food and Drug Administration. The regulation lists nine components that establish the practices the food industry must follow for processing safe food under sanitary conditions. Because hazards generally come from three main areas – people, ingredients or environment – these nine components aim to pre-emptively control these hazards and include:

- Personnel

- Plant and grounds

- Sanitary operations

- Sanitary facilities and controls

- Equipment and utensils

- Processes and controls

- Warehousing and distribution

- Holding and distribution of human food by-products for use as animal food

- Defect action levels

To ensure cGMPs are correctly followed and implemented, organizations must properly develop, adequately write and firmly train employees to the cGMPs. These practices involve the everyday parts of operations in a food processing facility where the plan can get derailed. Even the most robust food safety systems can fail if any of the fundamentals of food handling, facility and equipment care, and safe general upkeep are not adequately addressed. Basic cGMPs, such as wearing proper hair restraints or not wearing jewelry, acrylic nails and even eyelash extensions, are frontline safeguards to keeping unwanted items from being introduced into food products. Other simple steps, including color coding utensils used with allergens, address possible cross contact issues through proactive policies.

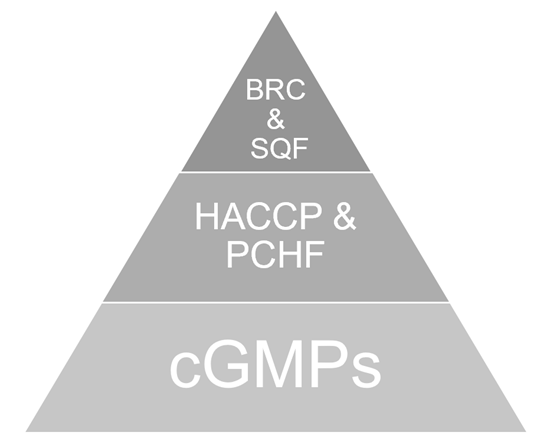

Once cGMPs have been established, food processors can move on to implementing plans for Hazards Analysis and Critical Control Points (HACCP) or Preventive Controls for Human Food (PCHF), with the end goal of attaining higher quality certifications, for example, under Safe Quality Food (SQF) or the British Retail Consortium (BRC). This progression is reflected in the pyramid below.

Employees are your greatest assets. They must be put in the best position to succeed. As part of this, effective and concise written work instructions that address cGMPs should be put in place, and adequate training for employees should be provided. Their success is the company’s success. Without the foundation of well-trained employees practicing cGMPs, a robust food safety system will likely never be attained.

For further training on cGMPs and food safety, The Center is now offering various in-person and virtual training courses tailored to food processors, including one course focused on cGMP Readiness. Learn more about our food safety courses and register for an upcoming class here.

MEET OUR EXPERT

John Spillson, Food Business Development Manager & Lean Business Advisor

John Spillson, Food Business Development Manager & Lean Business Advisor

John Spillson joined The Center in 2014 to develop and expand the food program. His experience in operating his own business has given him knowledge in production, sales, food safety, marketing, warehousing and logistics. John works to help companies understand that food processing is manufacturing, enabling them to embrace the same strategies that have aided traditional manufacturers for decades. As a Lean Business Advisor, John uses Lean tools such as Value Stream Mapping, 5S, Kaizen events, Standard Work and Problem Solving to help manufacturers of all types effectively reduce waste, improve efficiency, manage risk and improve corporate culture.

Since 1991, the Michigan Manufacturing Technology Center has assisted Michigan’s small and medium-sized businesses to successfully compete and grow. Through personalized services designed to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.the-center.org.

Categories: Food Processing