8/17/2018

BY: GEORGE SINGOS

We recently posted a blog about the importance of cascading policy deployment in achieving business visions. While this company-wide alignment is essential to realizing strategic goals, progress cannot be made without maintaining a strong sense of how well the business is performing. This is where Key Performance Indicators (KPIs) come into play. By establishing, monitoring and analyzing KPIs, such as on-time delivery, changeover time or schedule bumping, companies will be equipped with the data and guidance necessary to align their business toward success.

However, looking at internal KPIs without knowing where your company stands within the market can make it difficult to fully comprehend how well your business is operating. To help manufacturers compare their KPIs with those of like companies, The Center developed the Transformation Planner. This assessment tool gathers data about an organization’s operations through nine KPIs to assess a company’s effectiveness. By using this assessment, companies will determine:

- Where does your company stand? All data is compared against The Center’s growing database of relevant, related companies. In doing so, businesses can discover how well their KPIs stack up against peers.

- What areas need improving? In analyzing these KPIs, companies can identify which metrics fall short of reaching goals. Once these areas have been identified, a deployment plan for improvement can be created.

Most manufacturers probably think they are already performing as effectively as possible. However, making even small changes to improve a few KPIs can have a dramatic impact on your company’s bottom line. For example, let’s look at how Acme Corporation tackled four of their problem areas to realize massive improvements.

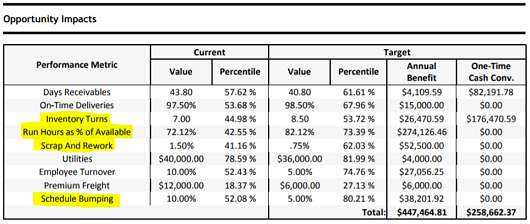

Acme’s journey began by completing the Transformation Planner with their company’s current business information. From there, The Center’s experts worked to identify which metrics were weaker than peers’ values, essentially identifying which areas to improve. As seen below, this data was put into a table to compare current values with targeted values for each of the nine performance metrics measured, including both Acme’s values as well as placement among similar companies.

By evaluating these numbers, four significant areas of improvement were identified – Inventory Turns, Run as a % of Available, Scrap and Rework and Schedule Bumping – to boost Acme’s profitability and get their operations on track for success.

- Inventory Turns. This serves as a fundamental measure of lean performance and ability to convert expense into billings. A high Inventory Turns value often signifies a nimble company – one able to respond quickly to changes in demand. Low turns may result from excessive raw, finished or in-process inventory stocks. By identifying this as a weak point in Acme’s operations and increasing their Inventory Turns value from 7 to 8.5, a seemingly small improvement, Acme was able to gain an additional $26,470.59 each year, with $176,470.59 of cash not in Inventory.

- Run as a % of Available. The best measure of your equipment utilization is how many hours your processing lines or systems run in a year. Once the appropriate level of run time is determined, the actual number of hours running must be evaluated. The goal is to attack the drivers of downtime, including long or unnecessary changeovers, unreliable supplier delivery, poor housekeeping and materials management, inadequate preventive maintenance and poor breakdown prediction. For Acme, achieving a 10% increase in Run as a % of Available boosted their competitiveness by more than 30% as well as earned them an additional $274,126.46 annually.

- Scrap and Rework. Scrap is waste from errors in the manufacturing process, composed of both lost labor and loss of materials that cannot be salvaged. Scrap directly decreases profitability due to the loss of time and materials. The requirement to run more product to compensate for scrap has a rippling effect on on-time delivery, making current and subsequent jobs late. Rework is an expense of labor that can occur before or after a product ships, which involves modifying a product to get it to conform to customer specifications. By decreasing their Scrap and Rework value from 1.5% to 0.75%, Acme increased competitiveness by 20% and achieved an annual benefit of $52,500.

- Schedule Bumping. Interrupting a scheduled job often results in lost equipment run time, additional labor cost and poor delivery performance. Not only can "bumping" the scheduled job result in at least one extra changeover, but it also leads to more idle time and overtime pay for operators as well as increased charges for premium freight. Through targeting a 5% decrease in Schedule Bumping, Acme gained an additional $38,201.92 annually and boosted their competitiveness by nearly 30%.

As seen with Acme’s success, by identifying and tracking your company’s areas of weakness and making even small adjustments to operations, your business can realize significant benefits both immediately and down the line. No matter how well your business may be running now, there is always room for improvement.

To learn more about how the Transformation Planner can transform your business, click here or contact The Center at 888.414.6682.

MEET OUR EXPERT

George Singos, Business Leader Advisor

George Singos is the Business Leader Advisor for the Michigan Manufacturing Technology Center. He has accumulated more than 30 years of manufacturing experience in Business Development, Sales & Marketing Management, Project Planning, Quality Management, Costing and Scheduling. Prior to joining The Center, George worked in International Business Development, where his primary focus was growing International Sales in Europe and East Asia while supporting North American, South American and ASEAN operations.

Since 1991, the Michigan Manufacturing Technology Center has assisted Michigan’s small and medium-sized businesses to successfully compete and grow. Through personalized services designed to meet the needs of clients, we develop more effective business leaders, drive product and process innovation, promote company-wide operational excellence and foster creative strategies for business growth and greater profitability. Find us at www.the-center.org.

Categories: Continuous Improvement,

Finance,

Growth