SUPERIOR FABRICATION: Staying Competitive During A Labor Shortage With Lean

Working with The Center-NI was made easy by their support, practical approach and knowledge of the subject matter. They accommodated our needs with a high level of instructor experience and a training schedule to minimize production downtime while improving our Production Team’s knowledge and execution.

-- Joe Dobrowolski, President-Superior Fabrication

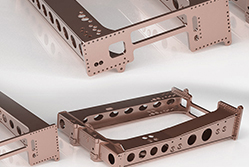

Superior Fabrication (www.supfab.com) was founded in 1979 as a defense contractor following the retirement of the Kincheloe Air Force Base in Michigan’s Upper Peninsula. Over time, the company’s focus shifted to providing high-end quality fabrication for a variety of industries, and in 1987, they began manufacturing rough terrain material handling masts and attachments. Superior Fabrication’s team of engineers also designs custom, heavy-duty steel fabrications and provides engineering services to customers. Superior Fabrication employs 101 at their facility in Kincheloe, Mich.

Challenge

Faced with a shortage of skilled labor, Joe Dobrowolski, President of Superior Fabrication, recognized his company needed to become as efficient as possible to continue to grow and remain a competitive, cost-effective option for their customers. Implementing Lean manufacturing tools would be key to achieving these goals.

Solution

Superior Fabrication reached out to the Michigan Manufacturing Technology Center – Northern Initiatives (The Center) to train all team leads on Lean principles. The Center guided 20 of Superior Fabrication’s leaders through a simulation of their production floor. The simulation was completed eight times, introducing a new Lean concept or tool each time. Superior Fabrication then applied the Lean tools to their plant, investing in three automated welding machines and a subassembly robot to maximize efficiency and improve throughput. Keeping labor costs down and reducing waste through systematic changes has enabled Superior Fabrication to diversify their product line and grow a stronger sales pipeline. Instead of hiring 10 people to weld three different products, they maximized time and utilized the skills of four workers to program robots to perform the tasks. These investments have led to a more engaged workforce, as well as new and retained sales. Cost savings generated by Lean improvements have benefited the customer and ultimately, the end user.

Results

- Increased Sales: $695,000 was attributed to new orders and new customer acquisition. Reduced labor rates and tasks, as well as reduced time for welding and machine processes due to Lean initiatives, enabled them to be more competitive in quoting new work. Retained Sales: $14M was attributed to retaining and increasing orders from existing customers. These retained sales were realized by keeping costs down and continuing to improve throughput.New Investment: $250,000 was invested in tooling and process enhancements on the plant floor to support and enhance Lean objectives. Fixtures and lifting aids were added to support and sustain processes.Retained Jobs: 20