PAK-RITE INDUSTRIES: The Total Package

With MMTC’s guidance and training, we have initiated LEAN manufacturing concepts that have changed our company’s culture and equipped us with the ability to reconfigure our entire plant layout in just two stages.

-- Rory M. Renaud, Chief Financial Officer-Pak-Rite Industries

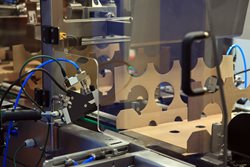

With 300,000 square feet of combined warehouse space and more than 60 years of industry experience, Pak-Rite Industries protects packages and processes for the automotive, retail, and light and heavy truck industries. Providing professional services of quality packaging, controlled storage, accurate distribution, and timely delivery, Pak-Rite Industries offers kit assembly, carton packaging, bagging, skin packaging, cold seal packaging, blister packaging, clam shell packaging, palletizing, and more. Pak-Rite Industries Inc. is located in Ecorse, Michigan just south of Detroit and employs 185 people.

Challenge

Pak-Rite Industries Inc. reached out to the Michigan Manufacturing Technology Center (MMTC), a NIST MEP affiliate to problem solve and overcome obstacles in the planning and deployment of its corporate goals while complying with new customer metrics to secure additional business. Achieving and sustaining these targets enabled Pak-Rite to win new kitting and light assembly work.

Solution

In order to increase capacity, a total reorganization and layout of the manufacturing and warehousing areas was necessary. Working with MMTC, Pak-Rite was able to free up and lay out 20,000 square feet of floor space for materials storage and work stations in support of this new business. Nothing was off limits, from knocking down interior walls to moving material, equipment and assembly work cells.The shipping area alone added eight new shipping lanes, allowing access to two docks which were previously blocked by walls. During this phase of implementation, the 90 station dealer and distribution sorting area was laid out and a standard work flow was created. This helped increase efficiencies in both labor and equipment utilization.The focused factory work cell concept was implemented to streamline Pak-Rite’s performance metrics and exceed its customer requirements. This required changing the production management organizational structure, including roles and responsibilities, and expectations for the Cell Leader, Line Leader, Expeditor, and Scheduler positions. Cross training and input from these stakeholders was an important element resulting in standard work and increased efficiencies.

Results

- Created 80 New JobsNew Sales of $6 MillionRetained Sales of $1.4 MillionPlant & Equipment Investments of More Than $270,000